Due to its unquestionable importance and widespread effect, dimensional control takes a significant share of the inspection routine carried out at Sun-Air Research Institute. Inspections and tests that were carried out sporadically at the beginning, have now been formed into a unified and comprehensive set of regulations and procedures with the growth and expansion of the institute. Periodic and case-based tool calibration is performed based on national and international standards and norms, with the output of detailed calibration reports.

Broadly speaking, the services provided can be categorized into the following:

- Dimensional control of parts and components.

- Executing performance tests

- 3D scanning

Dimensional control of parts and components

All parts and components in a project are inspected by trained and experienced personnel according to the project specifications and quality assurance guidelines. Inspection procedures are conducted utilizing calibrated test apparatus and according to ISO-17025.

Operator completing dimensional control report

Executing performance tests

After the manufacturing and construction of each part is completed, performances test are conducted according to written test plans. These tests range from the smallest components to a complete integrated system such as a wind turbine.

System operational test

3D Scanning

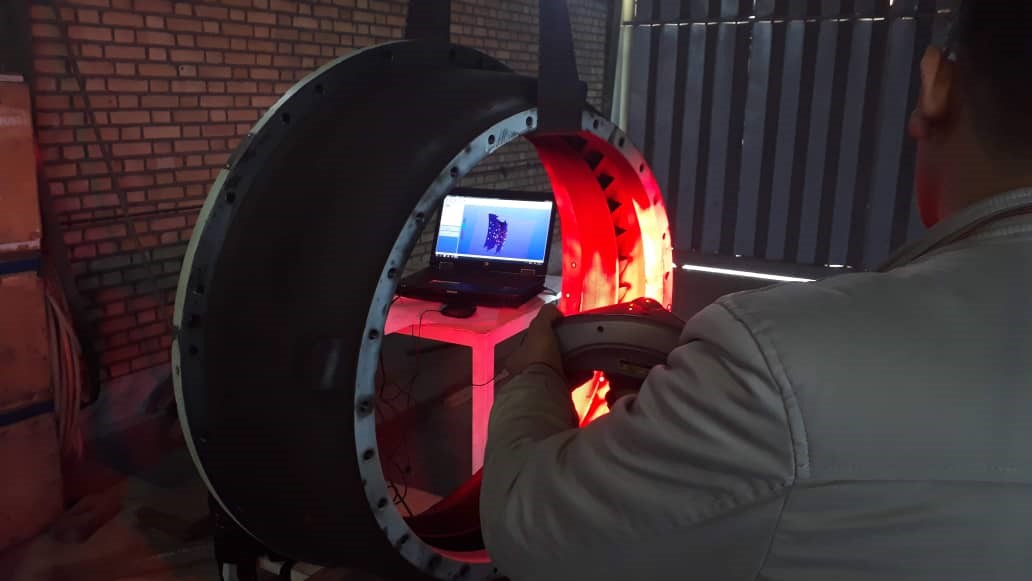

Reverse engineering of complicated industrial machines requires availability of 3D geometrical dimensions, usually as a cloud of points using 3D laser scanners or computed tomography. Usually for modeling complex parts, the relevant part is scanned and thereafter modelled via applicable software.

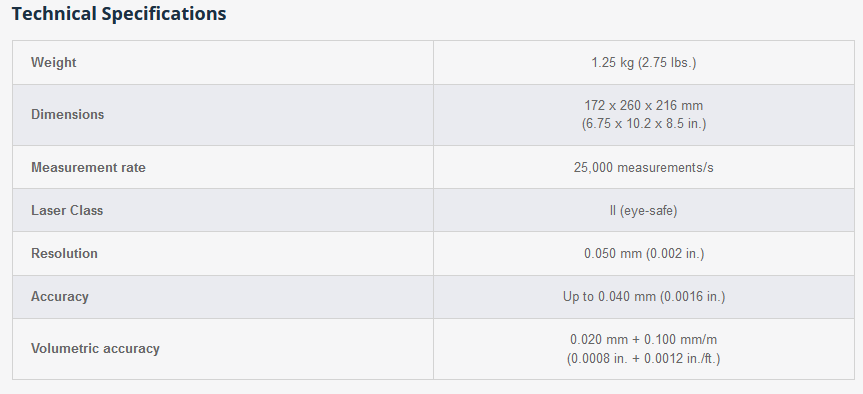

Dimensional control lab at this institute utilizes EXAscan 3D Scanner with high accuracy and precision. Regardless of the part’s dimension, this scanner is capable of recording 250,000 points per second in a contactless procedure. The scanner’s resolution is 0.05 mm with a precision of 0.02 to 0.04 mm, and stores the 3D file of the scanned part in the STEP format.

EXAscan 3D Scanner

EXAscan technical specifications

3D scan of turbine impeller

3D scan of rotor casing