As an essential concept in design and analysis of mechanisms especially entailing rotary components, the Vibration and Modal Analysis lab. has played a crucial role in the development of our products from the very beginning, with the utmost capability of providing the following services:

Modal Test:

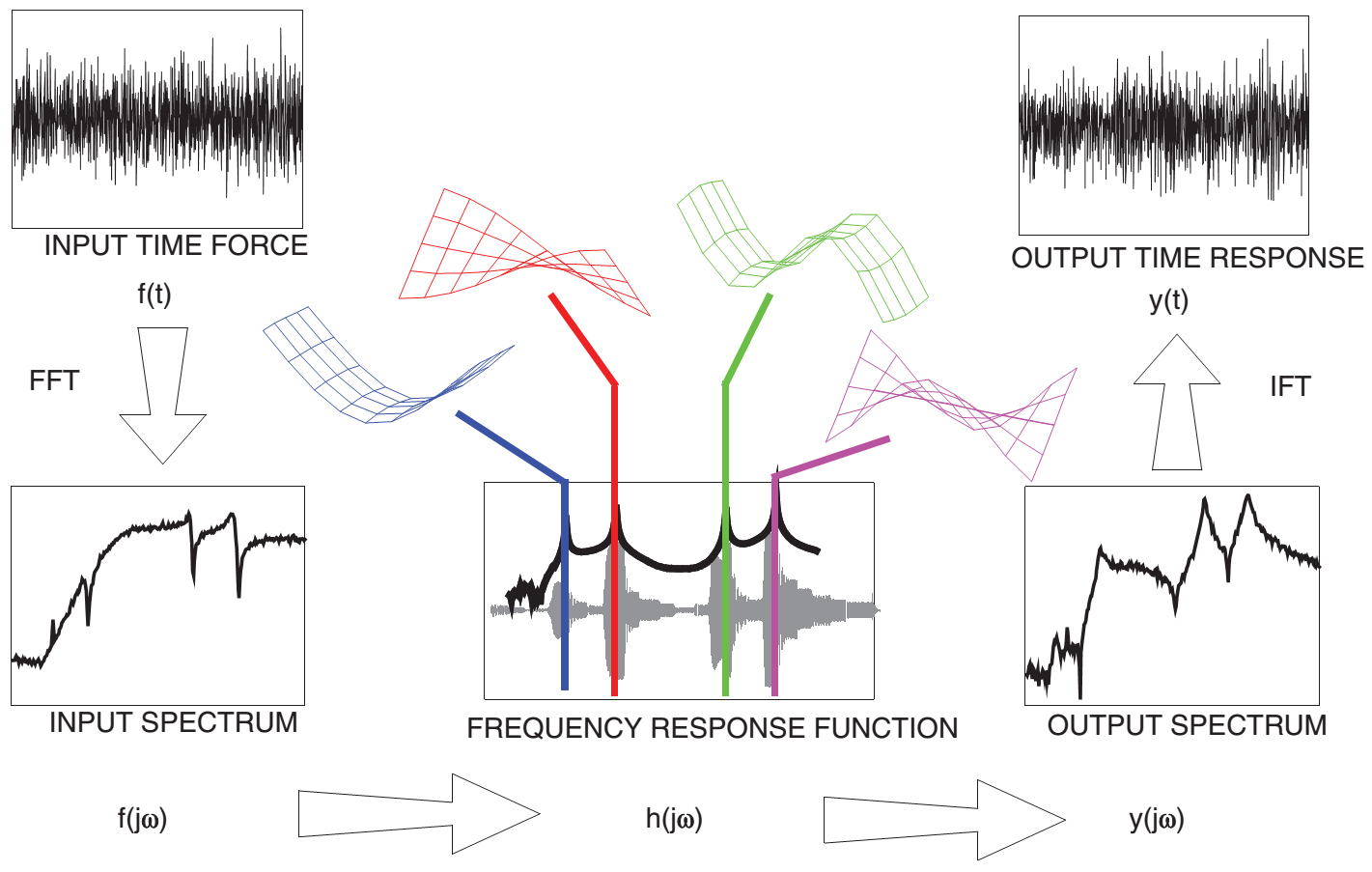

Dynamic properties such as natural frequencies, mode shapes, and damping coefficients are inherent characteristics of components that describe the dynamic response behavior. Modal tests and analysis are carried out to capture these properties.

Modal analysis procedure

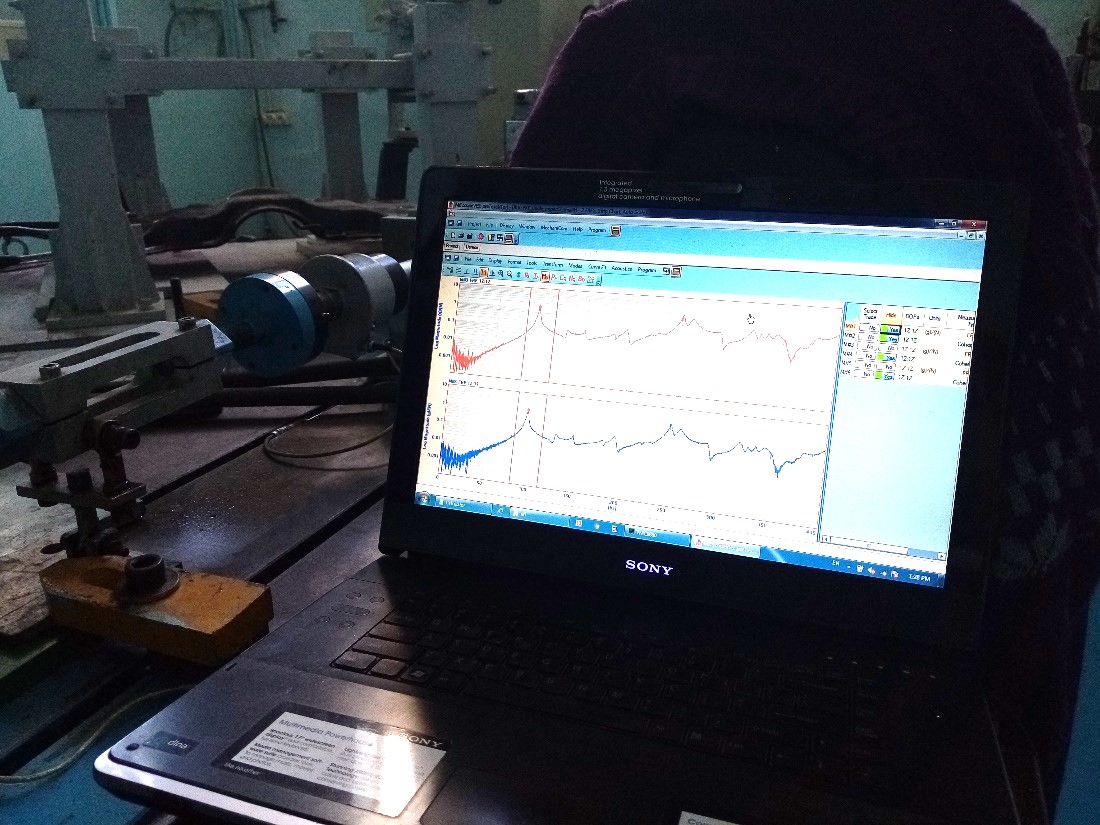

Automobile cross-member modal test

Frequency response function of automobile cross-member

Condition-based Monitoring

Condition-based monitoring is a key technique for assuring efficiency and quality of products and is considered as a vital part of most of the engineering processes in industry. In essence, condition monitoring is the process of overseeing the machine’s health. This notion is readily adopted in many industries such as wind turbines, compressors, aerospace, and marine engineering.

Condition monitoring of a 250kW turbine manufactured at Sun-Air

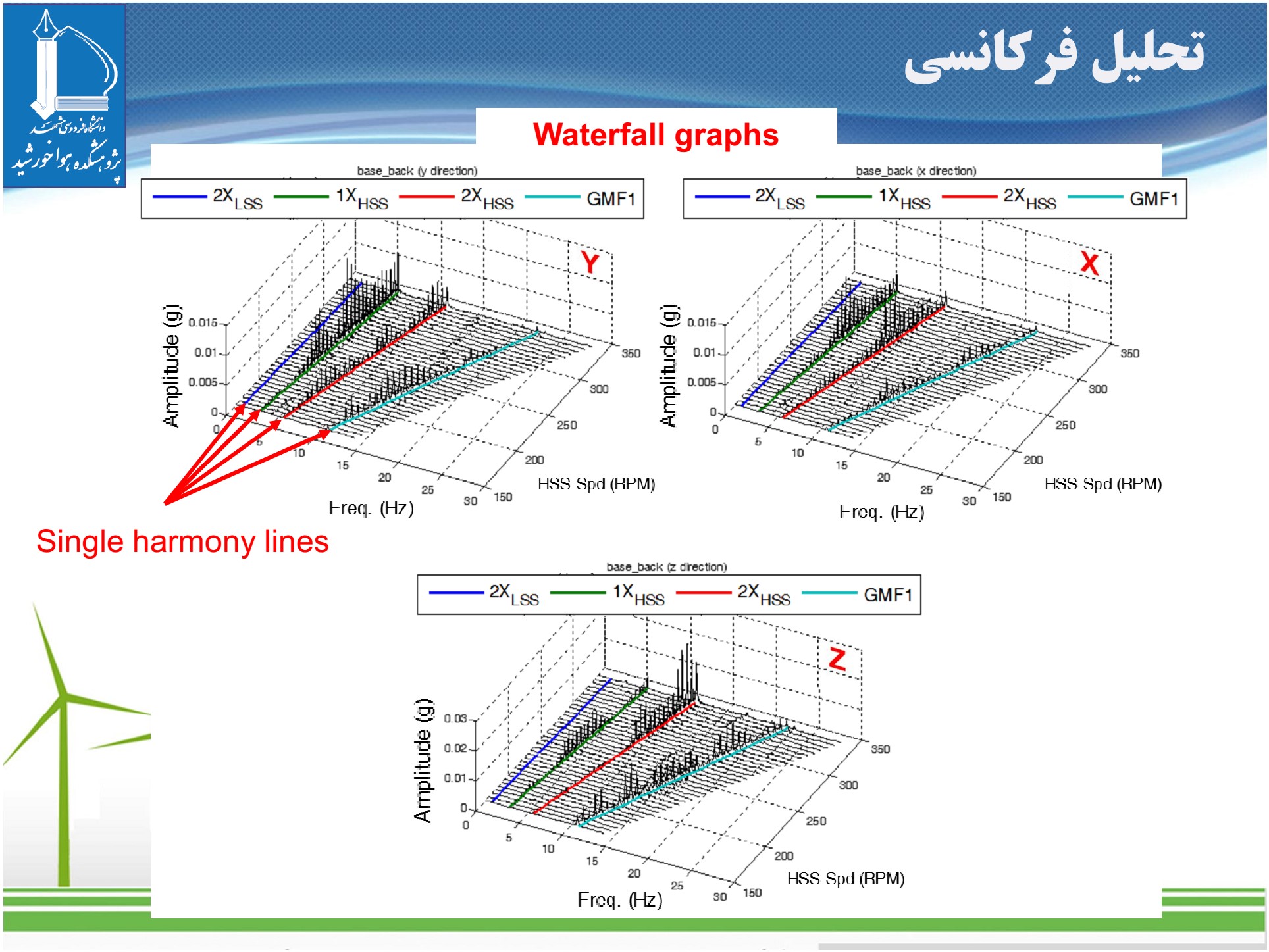

Waterfall analysis of Sun-Air 250 kW wind turbine base

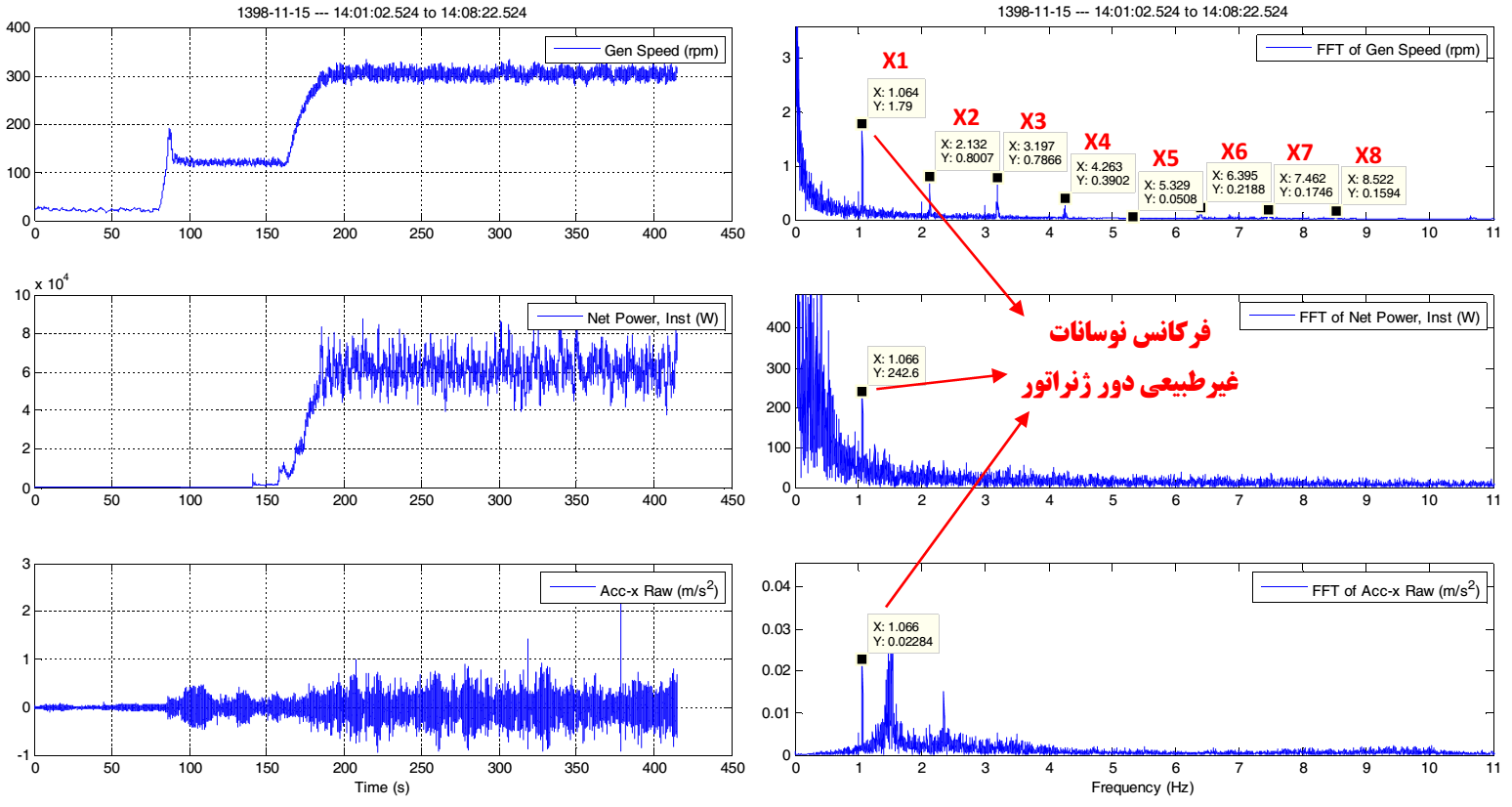

Vibrational Condition monitoring of Sun-Air 100 kW wind turbine