With over 10 years of active service and accumulated experience, and by employing the expertise and knowledge of a highly professional team, this institute is capable of offering the following services as part of this lab’s capability in providing practical solutions to a wide range of demands:

- Material tests to determine mechanical, physical and chemical properties, along with quality control checks

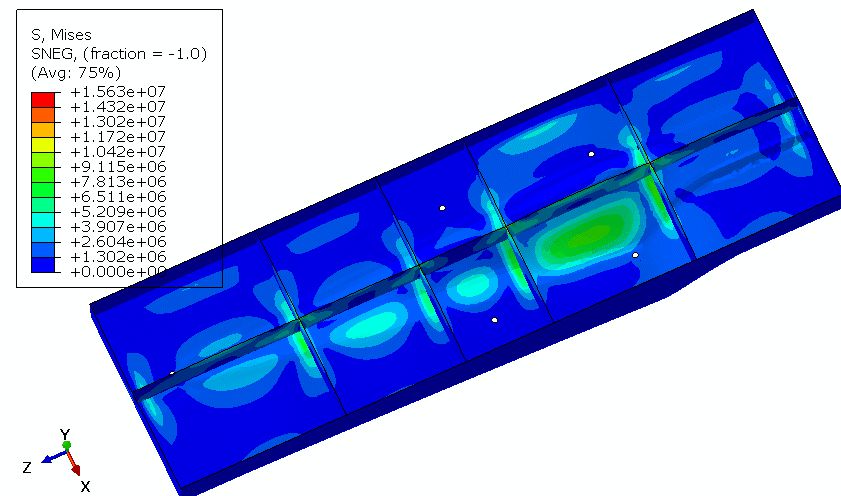

- Load calculations, design and simulation of composite parts and structures

- Manufacturing process plan for designing the mold and the component for Hand Lay-up, Vacuum Bagging, Bladder Molding, and Vacuum Infusion processes

- Design assembly systems and mechanisms

Design and analysis of blade composite mold

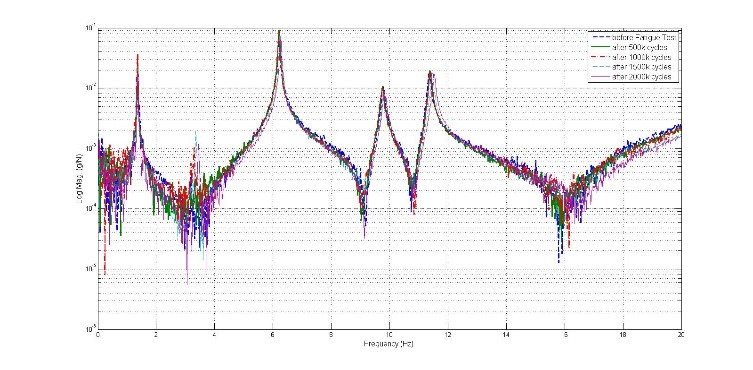

Modal test & analysis of a 100kW turbine blade

Vacuum resin injection

100kW turbine blade mold

1 kW turbine composite components

Design and fabrication of mold master

Processes are carried out with meticulous detail to ensure resin control and prevention of cavity and bubble formation in both large and small-scale products, while aiming to increase production speed in a cost efficient approach.