This fully equipped lab at Sun-Air Research Institute is a prominent center for research and development of photovoltaic cells, acting as a step towards harnessing solar power with a national and global impact.

Section of the Photovoltaic Lab

The following are some of the equipment available at this lab.

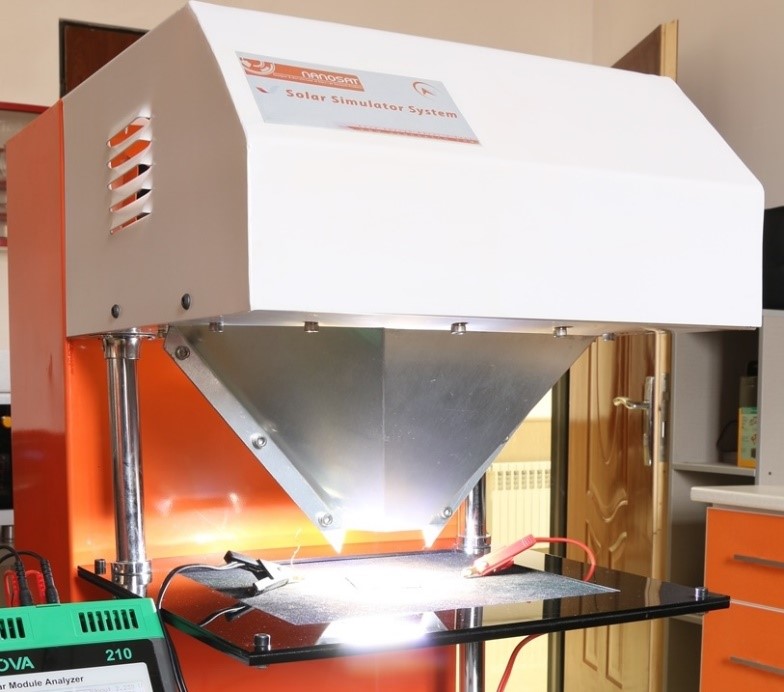

Solar Simulator

With a combined light source of Xenon and LED and capable of a radiation power of 1000 w/m2, sunlight illumination is replicated in a controllable setting. Tests are carried out according to AM1.5.

Solar Simulator

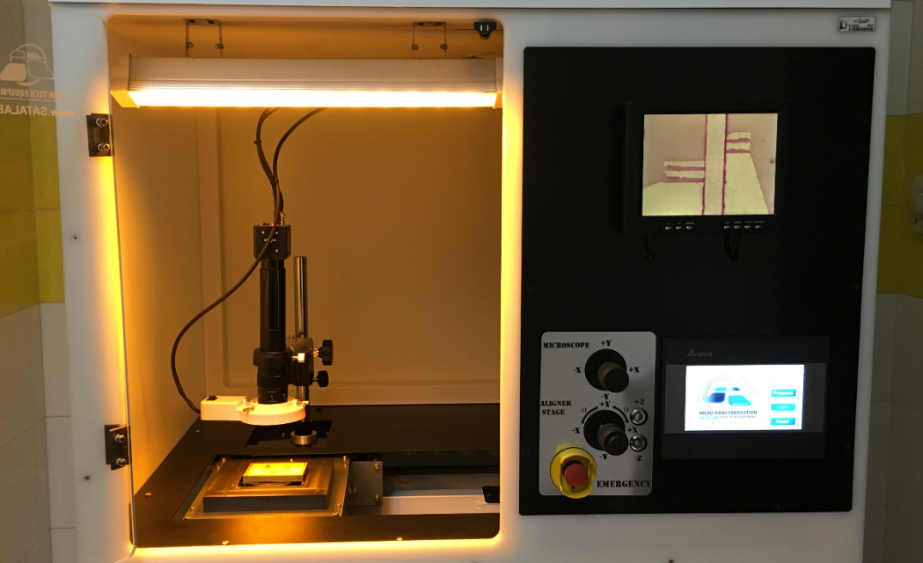

Lithography System

Capable of fabricating micro-channels, micro-sensors, and electric circuits and in the range of 20 to 200 µm, with a light source of 365 nm.

Lithography System

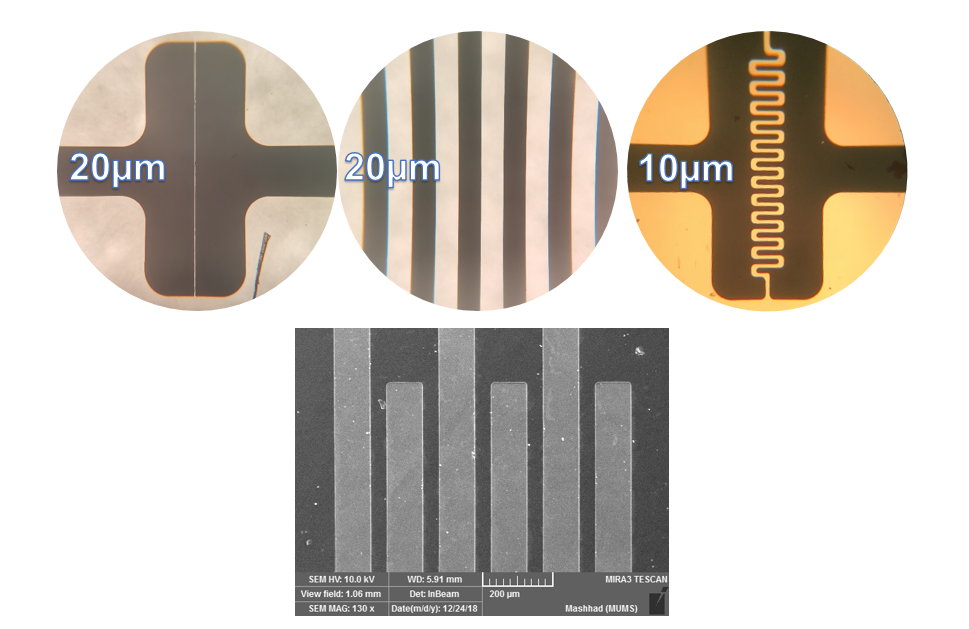

Samples of lithography process outcome performed in the lab.

Thermal Evaporation

Thermal evaporation deposition unit for Al, Au, Cu, Ag capable of layer disposition with a thickness of 10 to 150 nanometers for generating high quality electric connection.

Thermal evaporation deposition unit

Glove Box

Maintaining a controlled atmosphere of Argon and Nitrogen to create appropriate conditions for operations in a moisture free space.

Glove Box

Pyrolysis Spray

Capable of generating temperatures up to 450° C, a chemical solution with mineral or organic compound is prepared and sprayed on a hot surface and as a result, due to a chemical reaction in the subsurface layer, a thin layer of compound material is generated.

Pyrolysis Spray Unit

Hall Effect Measurement for Sheet Resistance

Measuring sheet resistance and mobility, with sensing devices capable of handling currents from 10 nA up to 1 A, and voltages from 30mv up to 1 v.

Sensing units

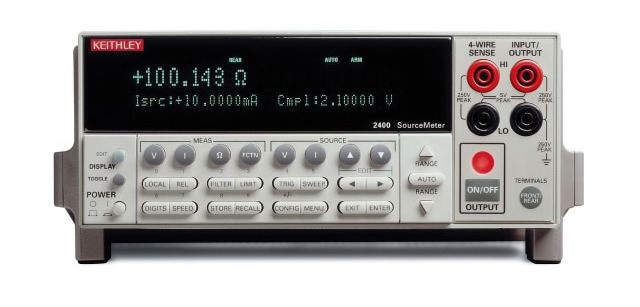

Current-Voltage Metering

Keithley 2400 I-V meter for measuring photo diode and photovoltaic characteristic curves, measuring resistance using the 4-point probe method, with a precision capable of measuring voltage and current at their respective micro levels.

Keithley 2400 I-V meter

Spin Coating Unit

Programmable to a maximum speed of 6000 rpm for high quality applying of thin films to substrates, ranging from a few nanometers to a few microns in thickness.

Spin Coating Unit

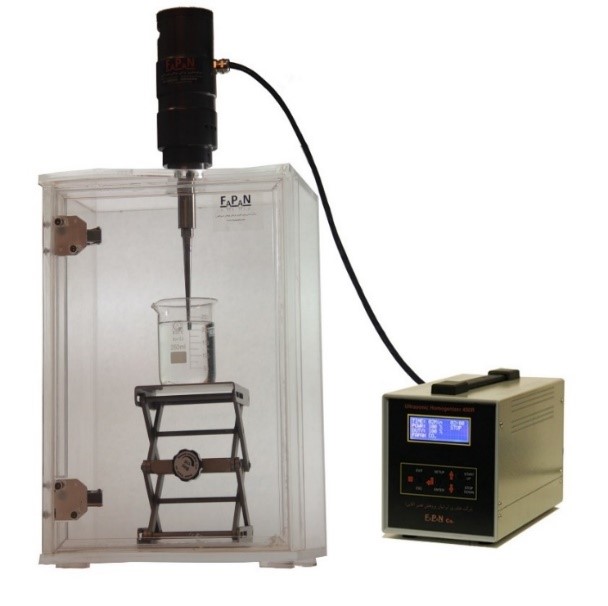

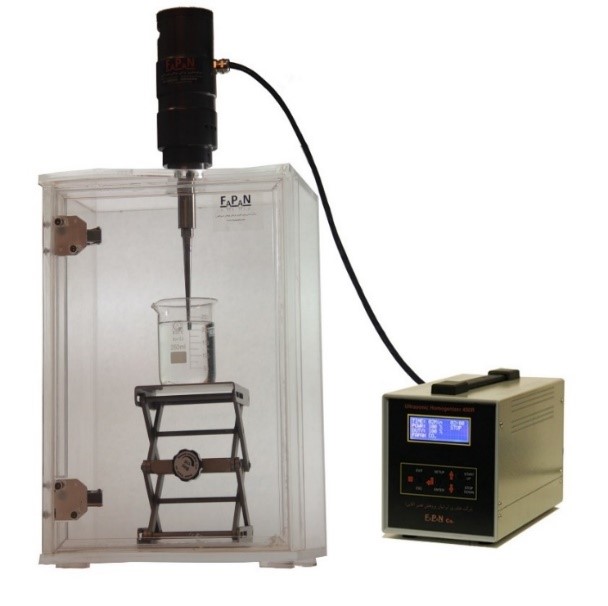

Ultrasonic Homogenizer

Employing ultrasonic waves, with an adjustable power range from 30 up to a maximum of 300 watts, and a probing tip of 4mm, and capable of continuous or pulsed work cycle to mix and homogenize solid-liquid and liquid-liquid suspensions.

Ultrasonic Homogenizer

Precision Scale

With the precision of 0.1 mg.

Precision Scale

Vacuum Pump

Two stage and single stage rotary vacuum pumps.

Vacuum pump

Heater Stirrer

Hotplate stirrer with a maximum temperature of 350°C and a rotational speed of 1500 rpm to keeps liquids circulating while being heated for necessary successive reactions.

Heater Stirrer

Ultrasonic Bath

120 volts with 40kHz frequency, fluid is agitated to clean objects of various types and sizes.

Ultrasonic Bath

Lab Heating and Drying Oven

55 lit. oven with 10 programmable modes, with a precision of 0.1°C and up to 200°C, for a variety of drying, heating, curing, and other applicable processes.

Lab oven